Knowledge: The Craftsman's Signature

The Craftsman’s Signature:That leather has skills! Proof of handicraft

The impression of the face changes greatly depending on how the eyeliner is drawn. It goes the same for leather products.

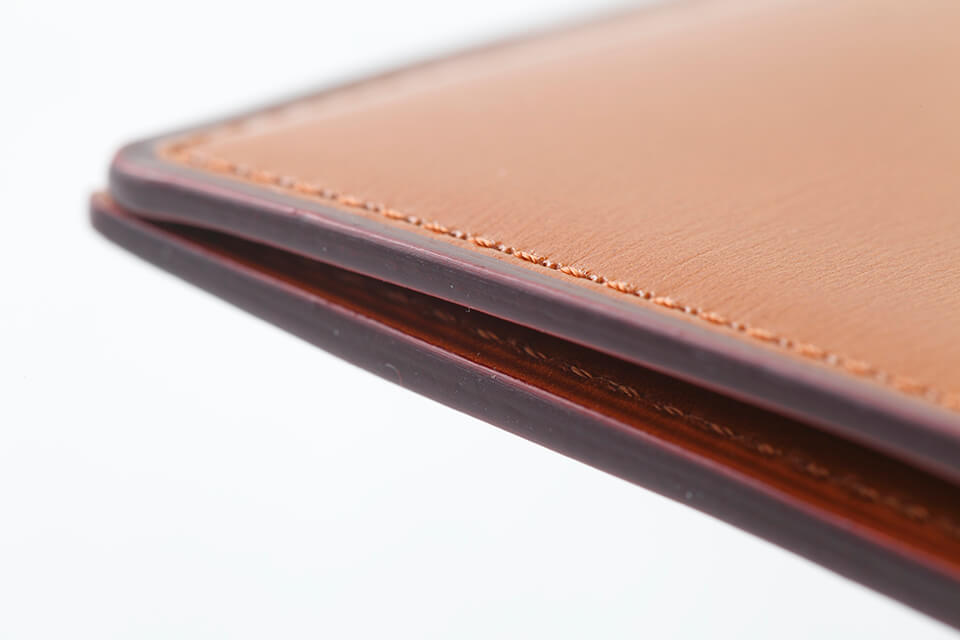

If you look carefully at the inside of the product, you can see that a line or crease is made parallel to the edge. This line is called an "ippon nen" or crease, and is one of the finishing processes. Draw a line with a trowel that dissipates heat only a few millimeters from the tip of the edge to improve the adhesiveness of the edge. In addition, a straight line without blurring has the effect of giving the product finesse.

On the other hand, "tamanen" is more for decorative purposes. This is a line drawn near the outer edge. The edge part can be emphasized, giving a crisp impression. For this reason, some products that prioritize a soft look do use this method. In addition, there is the two lined "nihon nen", and the type of creases differ depending on the image of the product you want to give. Veteran craftsmen do freehand creasing, but if they're inexperienced, they move their hands carefully along paper.

To be honest, the presence or absence of this crease does not significantly affect the functionality of the product. However, the appeal of Japanese manufacturing is the commitment to taking the time and effort just for this decoration.

You unconsciously feel the beauty. To the untrained eye, we don’t quite understand the reason. Craftsmen know that that single line brings the product together. The understand the secret to perfecting the overall balance.

God dwells in the details. And the craftsmen pour their heart and soul into finishing the details beautifully. In that sense, "Kikuyose" is exactly the highlight of the craftsman's skill. Kikuyose is a technique that folds the corners of bagged edge type leather products in a radial pattern. The finish is a chrysanthemum-like pattern, thus the stylish name kiku (chrysanthemum) yose (gather). Also called "kizami". It is mainly applied to products with curved corners, and this detail by skilled hands has an independent beauty in itself.

The basic process is to squeeze the leather thinly so that the corners can be folded neatly, and then carefully fold the leather inward. A highly skilled technique is required to naturally fold the loose leather that gathers in the corners, and it is said that "if you can do the kikuyose well, you can handle all the other work." By the way, the number of folds is different for each product, but odd numbers are said to be well-balanced.

While folds mean creases, it also refers to delicate subtleties such as "heart folds." Kikuyose is a technique that has exactly two subtleties. Take a look at the leather goods around you. You should be able to feel the delicate aesthetic of the craftsman in the carved folds.

Technique to finish up the product beautifully. However, it is the commitment of craftsmanship that does not end there.

With well-used hands and tools, and the delicate aesthetics of every detail, the leather products blossom.

The cut surface of leather is called the koba. It is said that it came to be called "koba" because it looks like wood grain (ko=wood, ba=edge), but it is rarely seen in the world left as is. What we often see in products, is the edge after the fine craftsmanship has been applied and beautifully finished.

Edge processing can be broadly divided into "cut edge type" and "bagged edge type". For the former, the cut surface is trimmed and colored, and if you are a skilled craftsman, you can make multiple pieces of leather look like one piece of leather. Shave, polish and paint. You are handling a small canvas. Carefully finish it evenly.

On the other hand, the "bagged edge type" is a method of covering the outer leather with the inner leather and adhering it. Since the cut surface is hidden, it gives an overall clean impression. In addition, there are various options depending on the type and style of the product, such as the "faced edge" two pieces of leather are joined with the edges turned back together and "turned edge" where the edge is sewn from the back of the leather and turned it over.

Such a small detail but such an important one. The impression of the entire product changes greatly depending on how the edge is finished. The fact that there are a wide variety of methods shows the importance of koba.

The manufacturing process that begins with tanning reaches its goal here. That is why the responsibility is great. Polish until you are satisfied, and a gem like no other will be born.